Anyone can smear something into drywall and make it look better for a day.

The difference shows up later. Under paint. Under light. Or when the wall shifts and the patch gives itself away.

We’ll break down how to patch a hole in the wall properly, based on size, structure, and finish. From quick small fixes to larger repairs that need backing, sanding, and texture matching, we’ll walk through what works and why.

Key Notes

Hole size dictates repair method, materials, and structural support needed.

Thin coats, wide feathering, and proper sanding determine whether patches disappear or telegraph.

Backing strips and reinforcement prevent cracking on medium and large drywall repairs.

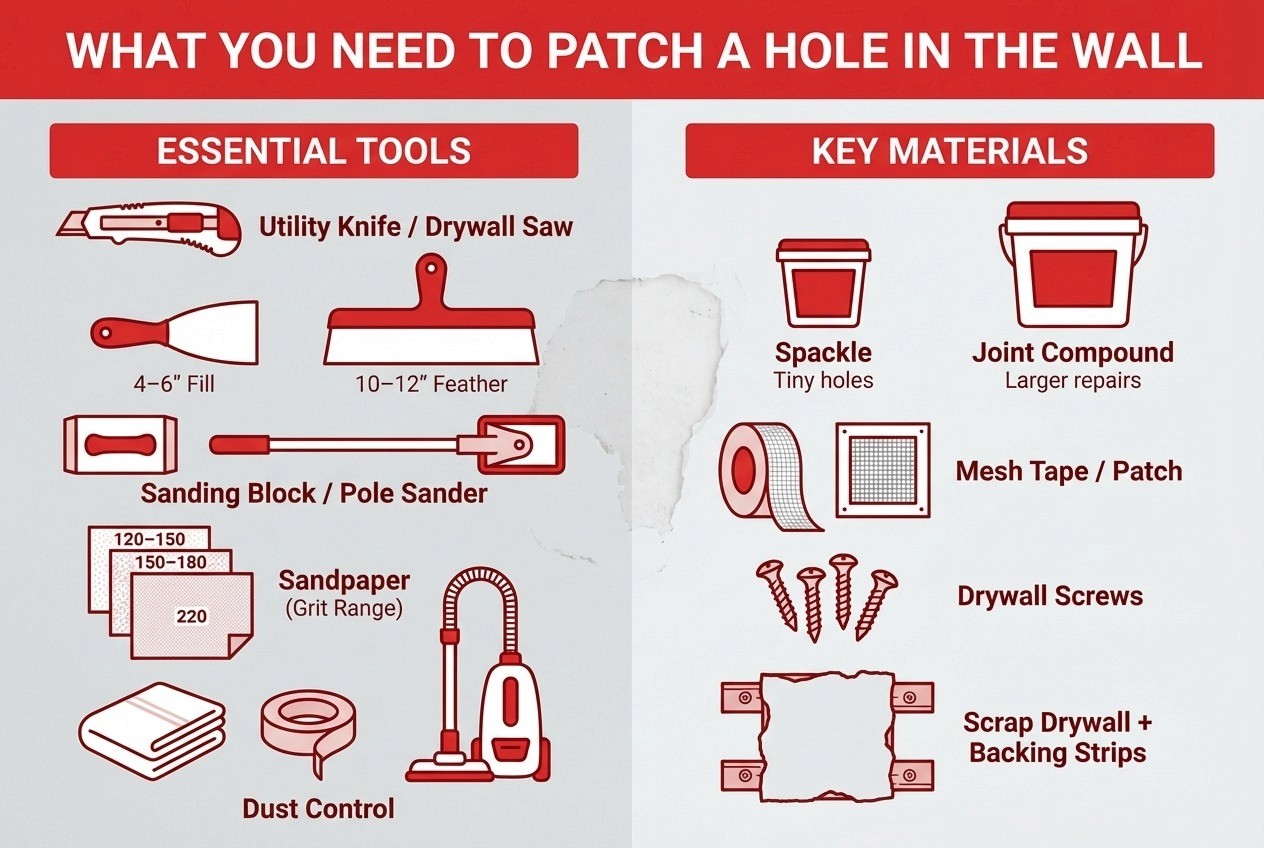

What You’ll Need To Patch A Hole In The Wall

You do not need a truck full of tools. But you do need the right stuff for the hole size.

Essential Tools

Utility knife (or drywall saw) for cleaning edges and squaring holes

Putty knife / joint knives

4–6 inch knife for filling and first coats

10–12 inch knife for feathering wider coats

Sanding block or pole sander

Sandpaper

120–150 grit for knocking down ridges

150–180 grit for feathering

220 grit for the final finish

Dust control basics

Drop cloths, painter’s tape, and ideally a vacuum or vacuum-assisted sander

Key Materials

Spackle (best for tiny holes) or joint compound (best for anything bigger)

Mesh tape or a self-adhesive patch for reinforcement

Drywall screws

Scrap drywall and backing strips (for large holes)

Spackle vs Joint Compound (What To Use)

You’ll see these words thrown around like they’re interchangeable. They’re not.

Spackle dries faster (often 30 minutes to a few hours) and is great for small holes, dents, and quick fixes. It shrinks less, which helps on tiny spots.

Joint compound (“mud”) dries slower (often 12–24 hours per coat for premixed) and is what you want for patches, seams, and anything requiring tape. It’s stronger, but it usually needs multiple coats.

Lightweight vs All-Purpose Compound

Lightweight compound sands easier and shrinks less. It’s a good DIY choice for finishing.

All-purpose compound is tougher and more versatile, but heavier and harder to sand.

If you hate sanding (most people do), lightweight is your friend.

Mesh Tape vs Paper Tape

Mesh tape is fiberglass, self-adhesive, and very DIY-friendly. Great for patches.

Paper tape is stronger and less elastic, which is why pros often prefer it on seams and corners.

How To Patch A Hole In The Wall By Size

This is where most people go wrong – they use the same method for every hole. That’s how you get a repair that looks okay today and shows up like a spotlight after paint.

Small Holes (Under 2 Inches)

Examples: Nail holes, small anchors, small dents.

Step 1: Clean The Hole

Use a utility knife to scrape away loose paper and crumbly gypsum. If you can pull it off with your fingernail, it needs to come off.

Wipe dust with a damp cloth. Not soaking wet. Just enough to remove residue.

Step 2: Fill With Spackle Or Joint Compound

Use a 4–6 inch putty knife.

Push the material into the hole first.

Then skim it flush across the surface.

Step 3: Let It Dry Fully

Spackle might dry in 30–60 minutes. Some take longer. Check the label, but also check reality. If it feels cool or soft, it’s not done.

Step 4: Sand Smooth

Use 150–180 grit. Light pressure. You’re blending edges, not sanding the wall into the next dimension.

Step 5: Second Coat If Needed

If you sanded and the hole “reappears,” apply a thin second coat. Let dry. Sand again.

Step 6: Prime And Paint

Always prime. Drywall patching changes how paint absorbs. If you skip primer, you can get flashing (a dull or shiny spot that screams “PATCH HERE”).

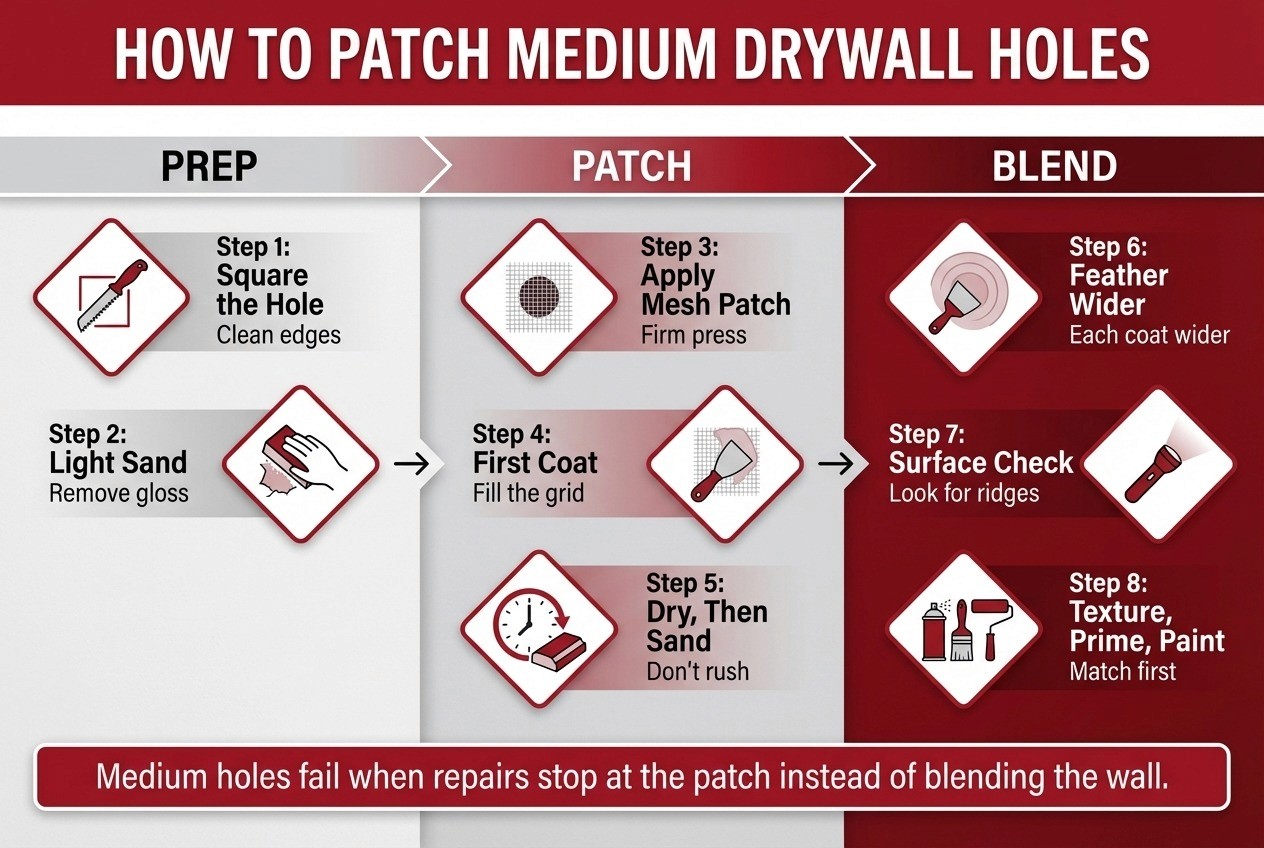

Medium Holes (2–6 Inches)

Examples: Doorknob damage, fist-sized holes, small plumbing/electrical cutouts.

For this size, you’re either using a mesh patch or you’re cutting and inserting a drywall patch. Mesh is usually the simplest.

Step 1: Square Up The Hole

Ragged holes are hard to hide. Use a drywall saw or utility knife and cut it into a neat shape. Square or rectangle is easiest.

Step 2: Sand The Surrounding Area Lightly

You want the patch to bond well. Knock off gloss and paint ridges.

Step 3: Apply A Self-Adhesive Mesh Patch

Center the mesh patch over the hole. Press it down firmly.

If it doesn’t stick well, the wall is probably dusty. Clean again and reapply.

Step 4: First Coat Of Joint Compound

Use a 6 inch knife. Spread compound over the patch in a crisscross pattern. The goal here is to fill the mesh grid and cover the patch completely.

Feather the edges out a few inches past the patch.

Step 5: Let It Dry, Then Sand Lightly

Premixed mud often needs 12–24 hours. Don’t rush this. If you sand too early, it pills up and tears.

Use 120–150 grit to knock down ridges.

Step 6: Second And Third Coats

This is where the invisible repair happens. Each coat should be wider than the last:

Second coat: Feather 6–10 inches beyond the patch

Third coat: Feather 10–12 inches or more

Use a wider knife (10–12 inch) on the later coats. Thin coats. Smooth pressure. You’re blending, not building a mountain.

Step 7: Final Sand And Surface Check

Use 180–220 grit.

Turn on a flashlight and shine it across the wall at an angle. If you see a ridge now, you’ll definitely see it after paint.

Step 8: Texture, Prime, Paint

If your walls are textured, match texture before painting.

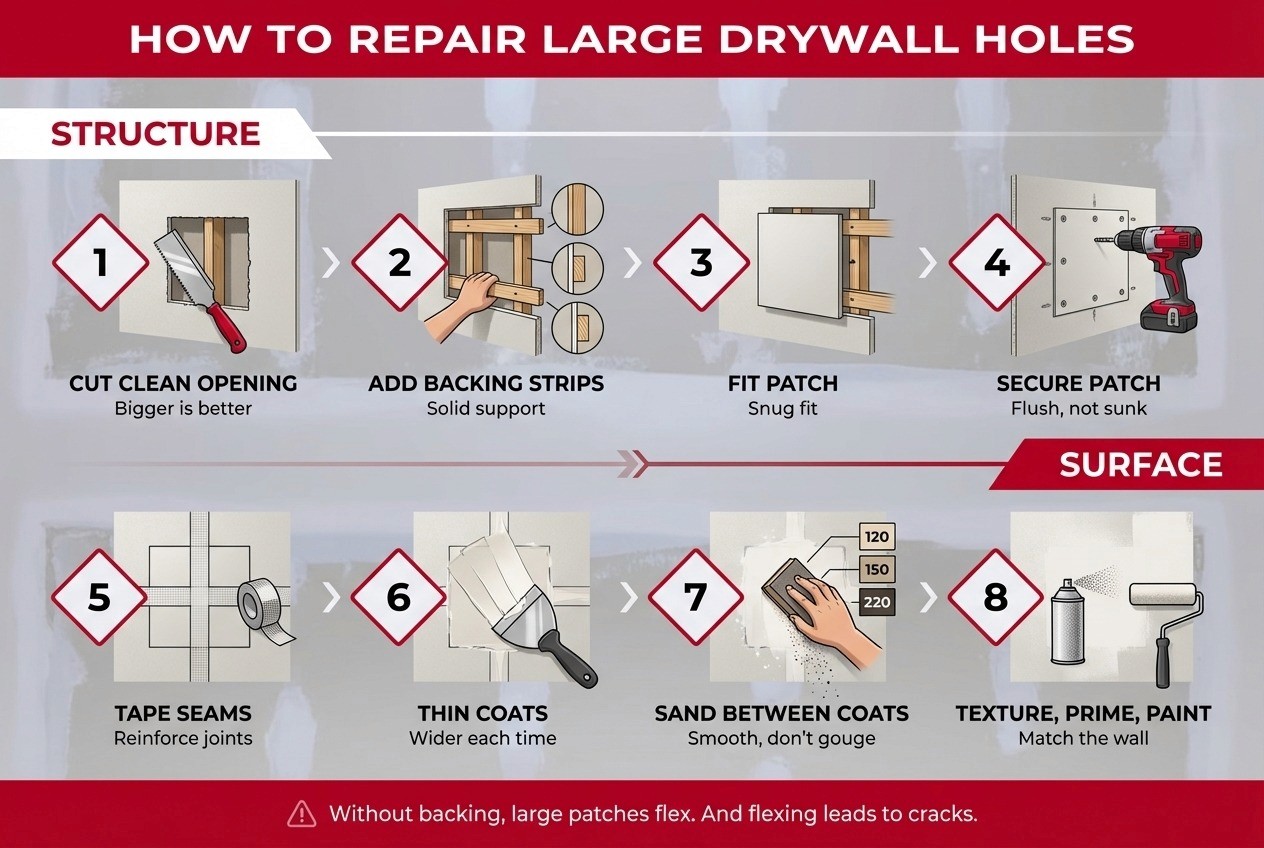

Large Holes (Over 6 Inches)

Examples: Kicked-in drywall, big access holes, removed vents, serious damage.

Large holes need backing. Without it, the patch can flex and crack later.

Step 1: Cut The Opening Into A Clean Square

Yes, bigger. Clean edges make cleaner repairs. Use a drywall saw and cut the hole into a square or rectangle.

Step 2: Install Backing Strips

Take two wood strips (furring strips or scrap wood) and slide them behind the drywall opening. Screw them through the existing drywall so they bridge the hole. You want solid support on both sides.

Step 3: Cut A Drywall Patch To Fit

Cut a piece of drywall that fits the opening. It should be snug, but not forced.

Step 4: Screw The Patch In Place

Use drywall screws. Make sure the patch is flush with the wall surface.

Step 5: Tape The Seams

Apply mesh tape over the seams. Press it flat.

(If you’re comfortable with paper tape, you can embed paper tape for extra strength. It’s more work, but it’s very durable.)

Step 6: Apply Compound In Thin Coats (3 Minimum)

First coat: Cover tape, fill seams

Second coat: Widen and feather

Third coat: Finish coat, wide feather

If you leave a hump, you will chase it forever with sanding. Thin coats win.

Step 7: Sand Between Coats

After first coat: 120–150 grit

After second coat: 150–180 grit

Final coat: 220 grit

Step 8: Match Texture, Then Prime & Paint

Large patches are where texture matching really matters.

Sanding: Where Most DIY Repairs Go Wrong

Sanding isn’t about grinding the wall flat. It’s about removing tool marks and feathering edges so the repair disappears.

A simple sanding rhythm:

Knock down ridges after coat 1

Feather after coat 2

Smooth after coat 3

And one thing that matters more than people think: dust control.

Drywall dust is insanely fine. It travels. It lingers. It finds every open drawer. If you’re not containing it, you’ll be cleaning for longer than you patched.

👉 At Fast Patch, we rely on vacuum-assisted sanding and full surface protection so dust stays controlled. If you’re DIYing, at least use plastic, tape off the area, and vacuum as you go.

Texture Matching After A Patch

A perfect patch with the wrong texture still looks like a patch.

Identify Your Texture

Look under angled light. Most homes fall into one of these:

Orange peel: fine, sprayed bump texture

Knockdown: flattened peaks, more dramatic pattern

Smooth: no texture, just clean skim coats

Orange Peel

Thin joint compound to a heavy-cream consistency.

Use a texture sprayer or aerosol texture can. Hold 8–12 inches away. Spray lightly. Build gradually. Feather the edges into the existing texture.

Knockdown

Spray a heavier orange peel texture first. Wait 10–20 minutes until it’s semi-dry (tacky, not wet). Then use a knockdown knife (12–18 inch) at a 15–30 degree angle to flatten peaks.

Smooth

Smooth walls are less forgiving than textured ones.

Apply 1–2 thin skim coats with a wide knife, feathering outward 12 inches or more. Sand progressively (150 → 220 grit).

Drying, Curing, Priming & Painting A Patched Wall

Painting too soon is how you get peeling, flashing, or a patch outline that shows through.

Dry vs Cured

Dry means the surface looks dry. Cured means the material has dried through.

Premixed joint compound often needs 24 hours per coat, sometimes more in cool or humid conditions.

Safe Paint Timing By Compound Type

Spackle: 30 minutes to 4 hours, often same-day paint

Hot mud (setting-type compound): 20–90 minutes, often paint-ready faster

Premixed joint compound: 24 hours per coat, often 2–7 days total for full patch and paint

Prime First

Primer equalizes absorption. It also helps you spot flaws before final paint. Once primer dries (often 30–60 minutes for latex), you can paint.

How Long Does It Take To Patch A Hole In The Wall?

A lot of DIY timelines are optimistic.

Small hole: under 1 hour active time, often same day finish

Medium hole: typically 1–2 days because of drying between coats

Large hole: typically 2–3 days (sometimes longer) if you want it to look right

If you use fast-setting compounds and keep the area warm and ventilated, you can shorten timelines. But rushing drying is where cracks and shrinkage show up later.

Do Drywall Patch Kits Work?

Yes… within their lane.

Patch kits work best for:

Holes under 1 inch (excellent)

Holes 1–5 inches (good, if the wall is stable)

They struggle when:

The hole is larger than 5 inches

The drywall is crushed or ragged behind the patch

You need texture matching (smooth walls are forgiving, textured walls are not)

If your patch kit leaves a visible grid pattern, it usually means the compound coats weren’t thick enough over the mesh or the feathering wasn’t wide enough.

Why Drywall Patches Crack Later (& How To Prevent It)

If a patch cracks later, it’s usually one of these:

Movement: Settling, temperature swings, truss uplift

Shrinkage: Thick coats of mud drying unevenly

Tape failure: Poor embed or weak reinforcement

Weak backing: Large patches flexing under pressure

Prevention That Works:

Use backing strips and screws on large holes

Apply 3 thin coats instead of one thick coat

Feather wide (12 inches is not overkill)

Prime before painting

When It Makes Sense To Call A Pro

DIY is fine when the hole is small, the wall is smooth, and you have time for dry cycles.

Calling a pro starts making more sense when:

The patch is on a ceiling or stairwell

You need texture matching (orange peel, knockdown, smooth)

You have multiple holes across rooms

You want dust contained (not floating through your house for days)

You need it done fast and paint-ready

Fast Patch is built for exactly that kind of job: one-visit drywall repairs whenever possible, 99% dust control, and texture matching that doesn’t leave a “repair square” behind.

Frequently Asked Questions

Can I patch a hole in drywall without sanding?

Technically, yes. Realistically, it will show. Sanding is what blends the repair into the wall. Skipping it almost always leaves ridges or flashing that become obvious once painted.

What’s the easiest way to patch a hole in the wall?

For holes under an inch, spackle and a small putty knife are the simplest route. Anything larger stops being “easy” and starts needing reinforcement to avoid cracks later.

How big of a hole can you patch without replacing drywall?

You can patch holes well over 6 inches as long as you add solid backing behind the wall. Without backing, larger patches flex and eventually fail.

Should I use caulk instead of spackle or joint compound?

No. Caulk stays flexible and doesn’t sand cleanly, which makes it a poor choice for flat wall repairs. It’s better reserved for corners or trim, not drywall patches.

Want To Skip The Dust & Guesswork?

Same-visit repairs, dust-free process, 1-year guarantee.

Conclusion

A patched wall can either disappear – or announce itself forever.

Patching a hole in the wall comes down to judgment as much as technique. Small holes forgive shortcuts. Medium holes demand patience. Large holes require structure, backing, and restraint with compound.

Rush the drying, skip the feathering, or ignore texture, and the repair shows up the moment light hits it sideways. Do it right, and the wall goes quiet again – no ridges, flashing, or “fixed spot” catching your eye every time you walk past.

If this feels like more than you want to tackle, a professional repair finished in one visit – without lingering dust – can save a lot of back-and-forth before paint ever hits the wall. Get your free quote now.